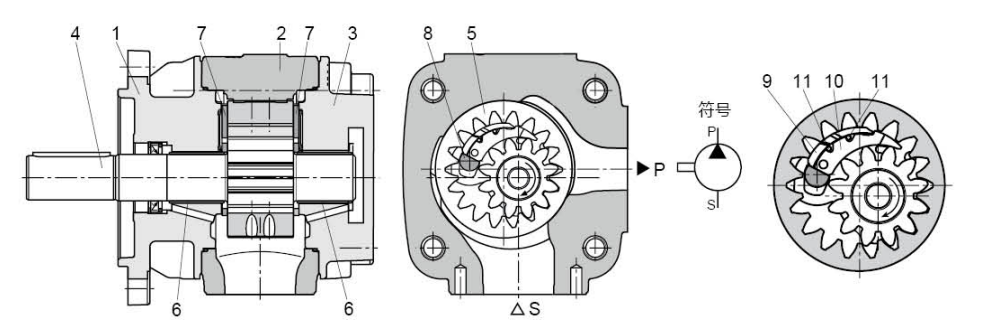

I-Priciple Diagram ye-Gear Pump

IIphampu ye-hydraulic ye-VGiyiphampu yegiya yangaphakathi yesinxephezelo se-backlash ene-ukufuduka okuhleliwe. Isakhiwo sayo esiyisisekelo yilesi: ikhava yangaphambili eqinile (1), umzimba wephampu (2), ikhava engemuva (3), shaft yegiya yangaphandle (4), iringi yegiya yangaphakathi (5), i-sliding bear (6), ipuleti lokusabalalisa uwoyela (7) , kanye nenduku yokubeka (8), ihlanganisa ibhodi elincane elicwebezelayo (9), ibhodi elikhulu elicwebezelayo (10) kanye nenduku yokuvala (11)

Ukumunca kanye nenqubo yokuphalaza

I-shaft yegiya yangaphandle (4) efakwe ngokuvumelana ne-fluid dynamics ishayela indandatho yegiya langaphakathi (5) lapho ijikeleza khona. Gcwalisa amafutha ngesikhala samazinyo esivuleke endaweni yokumunca uwoyela. Amafutha athuthwa asuka endaweni yokumunca uwoyela (S) aye endaweni yokucindezela (P) ngokusebenzisa indawo eseceleni ephakathi kwe-shaft yegiya yangaphandle kanye neringi yegiya eliphakathi. Ngenxa yalokho, amafutha akhishwa esikhaleni sezinyo elivaliwe futhi alethwe ku-port yamafutha okucindezela (P). Indawo yokumunca uwoyela kanye nendawo yokukhipha ihlukaniswa into yesinxephezelo se-radial (9 kuya ku-11) kanye ne-mesh yegiya phakathi kwegiya elingaphakathi leringi kanye negiya langaphandle.

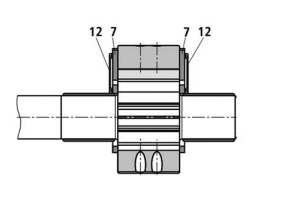

Axial isinxephezelo

Igumbi lokukhipha endaweni yokucindezela livalwe nge-axially ngepuleti lokusabalalisa le-tge iuk (7). I-pan yokusabalalisa uwoyela ibheke kude nokukhishwa kukhona uhlangothi olulodwa lucindezelwe yingcindezi efakwe (12). Lezi zinkambu zokucindezela zenza ipuleti yokusabalalisa uwoyela kanye nendawo yokukhipha ifinyelele ibhalansi, kusukela kumphumela omuhle wokuvala kufinyelelwa ngokulahlekelwa okuphansi kwemishini.

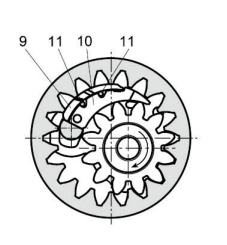

Isinxephezelo seradial

Isici se-radial compensation sihlanganisa ipuleti elincane elicwebezelayo(9), ipuleti eliyinhloko lencwele (10) kanye nenduku yokuvala (11). Ipuleti elikhulu elicwebezelayo (10) eliya endaweni eyindilinga yethiphu yedokodo le-shaft yegiya yangaphandle, icwecwe elincane (9) lixhunywe eduze nendawo eyindilinga yethiphu lezinyo lendandatho yegiya yangaphakathi, kanye nenduku yokuma. isetshenziselwa ukukhawulela ukunyakaza kwepuleti le-crescent endaweni eyindilinga.

Ngale ndlela, indawo yokucindezela ingahlukaniswa nendawo yokuncela ngokulungiswa okuzenzakalelayo kwemvume. Lokhu kuyimfuneko yokugcina ukusebenza kahle kwevolumu ephezulu ngokuqhubekayo kuwo wonke amahora okusebenza.

Amazinyo

I-toothing ene-involute flanks ifaka ubude be-meshing ende bokugeleza okuphansi nokushaya kwengcindezi ngakho-ke iqinisekisa ukusebenza komsindo ophansi.

Ukuqokwa kwemodeli

| VG1 | -63 | R | E | W | -A1 |

| Uchungechunge | Ukususwa kwe-ml/r | Ukuzungezisa | Uhlobo lwe-shaft | Izinto zokuvala | Inombolo yomklamo. |

| VG0 | 8, 10, 13, 16, 20, 25 | Ukubuka okuvela ekugcineni kwe-shaft yephampu R= Isandla sokudla sokulandela iwashi L=Isandla sobunxele ngokuphikisana nokuhamba kwewashi | E=i-shaft yokhiye oqondile R=Ishafi yomugqa | W= NBR V=FKM | A1 |

| VG1 | 25, 32, 40, 50, 63, 50H, 63H | ||||

| VG2 | 80, 100, 125, 145, 160 |

Amashaft for futha

Ukuhlanganisa iphampu

Ukubukwa kwendawo yokusebenza

Ukuphathwa kwe-6S

Isicelo

Ingasetshenziswa kabanzi embonini, njengomshini wepulasitiki, umshini wezicathulo, umshini wokuphonsa ukufa kanye ne-forklift nezinye izimboni uhlelo lwe-hydraulic, ikakhulukazi i-servo variable frequency drive system yokonga amandla.

Amaphuzu okunakwa okufanele asetshenziswe

1. Ukufakwa kwepompo yamafutha

- Ngokusemandleni akho, ukuhlanganisa okuvumelana nezimo kusetshenziselwa ukuxhumana phakathi kwe-pump shaft kanye ne-motor shaft ukugwema umzuzu wokugoba noma i-axial thrust. Iphutha eliphezulu elivumelekile le-coaxiality phakathi kwe-pump shatf ne-motor shaft ngu-0.15mm.

2. Uxhumano lwe-inlet ne-outlet

- Khetha ububanzi bangaphakathi bepayipi ngokuya ngembobo kawoyela yephampu kawoyela (isivinini sokungena esilungile singu-0.6-1.2m/s);

- Izilinganiso zokuklama zolayini wokudonsa wokudonsa kufanele zihambisane nokucindezela kokusebenza kwe-inlet evumelekile (inani eliphelele elingu-0.8bar kuya ku-2bar), futhi kumelwe kugweme ukugoba ulayini wokudonsa wepayipi kanye nenhlanganisela yamashubhu amaningana okumunca iphampu;

- Uma kusetshenziswa i-fliter yokumunca uwoyela, kunconywa ukuthi isihlungi sokumunca uwoyela sikhethwe ngokuya ngokugeleza okuphezulu kwepompo yamafutha, iphindwe yi-coefficient yezikhathi ezingama-2-3, futhi ukunemba kokuhlunga okuphelele kungu-50-180um. Kumelwe kuqinisekiswe ukuthi ngisho noma isihlungi singcolile, ngeke sidlule ukucindezela okuncane okuvunyelwe kokusebenza kwe-inlet yesistimu;

- Ukujula kokucwiliswa kweshubhu lokumunca elikhethiwe kufanele kujule ngangokunokwenzeka. Ama-currents e-Eddy akufanele akhiwe ngisho nasezingeni eliphezulu lokugeleza, ngaphandle kwalokho kuyoba ingozi yokudonsa umoya nokukhululwa.

- Ekwakhiweni kwepayipi lokumunca, i-oyili yokufaka uwoyela ayinconywa ukuthi ifakwe iqonde phansi. Uma ithangi likawoyela litholakala ngaphansi kwepompo likawoyela, indawo yokungena kawoyela kufanele ibe phezulu noma izinhlangothi zombili ezivundlile.

3. Inhlanganisela futha

- Lapho uhlanganisa amaphampu, kuyadingeka ukuqinisekisa ukuthi isigaba ngasinye sihambisana nosuku oluvumelekile lokusebenza lwezinhlobo zamaphampu ezifanele;

- Isiqondiso sokujikeleza kwawo wonke amaphampu ahlanganisiwe kufanele afane;

- Amaphampu anetorque ephezulu, ukugudluka okuguquguqukayo noma umthwalo osetshenzisiwe uzohlinzekwa njengesigaba sokuqala sepompo ehlanganisiwe;

- I-torque ephezulu ye-shaft drive kufanele ihlolwe umhleli wephrojekthi ukuze uthole izinhlelo zokusebenza ezahlukahlukene.

I-torque enkulu evumelekile (Nm)

I-torque ephelele yepompo ehlanganisiwe akufanele idlule i-torque enkulu yokushayela.

Ukuhogela okuhlanganisiwe akuvunyelwe.

Idizayini ye-pump shaft yangemuva kufanele ibe "R" (i-spline).

4. Ukusebenza kokuqala

- Hlola ukuthi isistimu ye-hydraulic ifakwe kahle futhi ixhunywe ekuqaleni kokuqala;

- Ngaphambi kokusebenza, kufanele ngokusebenzisa ishubhu lokumunca noma umugqa wokugeleza wangaphakathi ogcwaliswe ngephampu kawoyela odonsa amanzi, ivalvu yokukhulula uwoyela, uvule isistimu ngaphansi kwesimo sokungalayishi izinjini ezisebenzayo, kuhlale iphampu kawoyela wokugcoba eyanele, futhi kukhiphe umoya epayipini (amafutha ungabeki i-valve yokusiza, njengokuthi isistimu ingasebenzisa ijoyinti lokuthekelisa lephampu phumuza kancane, ezinye izindlela, ukuvuza kwegesi ephumayo Lapho amabhamuza engasaveli kuwoyela avuzayo, ingxenye exegisiwe izoba ikhiyiwe ngokuya nge-torque ecacisiwe: lapho usebenzisa le ndlela, kufanele ibe ngaphansi kwesimo sokucindezela okuphansi futhi iqinisekise ukuthi ingcindezi ayivuki.

- Ayikwazi ukuqala ukulayisha, ngaphandle kwalokho kuzodala umonakalo wangaphakathi wepompo yamafutha.

- Ngemva kokusebenza okuphindaphindiwe kwamachashazi, umsindo wokumunca uzonyamalala. Uma umsindo wokuxuba umoya ungashabalali ngemva kokusebenza kwamachashazi okuphindaphindiwe izikhathi ezimbalwa. Kufanele kube ukuthi kukhona ukuvuza komoya epayipini ohlangothini lokungena.

5. Isondlo

- Ukuze kuthuthukiswe ukuphakanyiswa kwesevisi yephampu kawoyela, ukudlidliza okungavamile, umsindo, izinga lokushisa likawoyela, isimo sikawoyela wesistimu ye-hydraulic, ukuthi akhona yini amabhamuza ethangini nokuthi kukhona ukuvuza nezinye izinkinga kufanele kubhekwe njalo futhi kugcinwe ngaphakathi. isikhathi;

- Wonke amaphampu kawoyela aphumelele ukuhlolwa kokusebenza ngaphambi kokushiya imboni. Noma iyiphi inkampani noma umuntu ngeke ahlakaze, ahlanganise kabusha noma aguqule amaphampu kawoyela ngaphandle kwemvume yenkampani. Uma eqaqa, ehlanganisa kabusha noma eguqula amaphampu kawoyela ngaphandle kwemvume yenkampani, akukho phakathi kombiko wokukhanda wenkampani futhi inkampani ngeke ithathe noma yimuphi umthwalo wemfanelo.