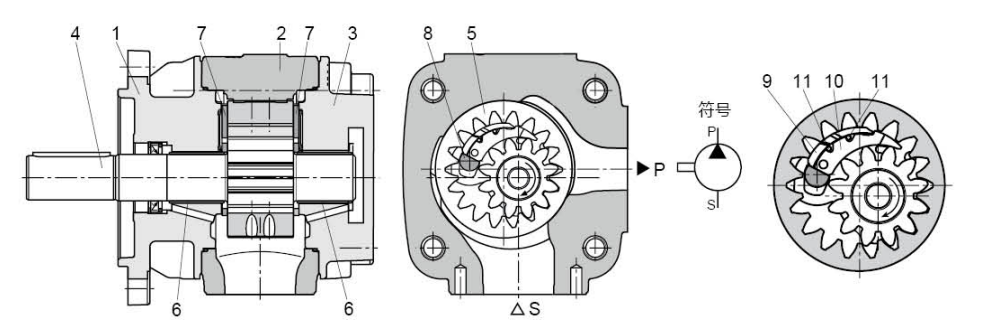

Umzobo oyiNqobo weMpompo yeGear

Iimpompo ye-VG ye-hydraulicyimbuyekezo yangaphakathi impompo yegiya yomqolo eneukufuduswa okusisigxina. Ulwakhiwo lwayo olusisiseko kukuba: isigqubuthelo sangaphambili esingaphakathi (1), umzimba wempompo (2), isigqubuthelo esingasemva (3), ishafti yegiya yangaphandle (4), iringi yegiya yangaphakathi (5), isilayidi (6), ipleyiti yokuhambisa ioli (7) , kunye nentonga yokumisa (8), iqulathe ibhodi encinci yecrescent (9), ibhodi engundoqo eceba iceba (10) nentonga yokutywina (11)

Inkqubo yokufunxa kunye nokuchitha

I-shaft yegiya yangaphandle (4) efakwe ngokwe-fluid dynamics iqhuba i-ring yangaphakathi yegiya (5) kwicala lokujikeleza elibonisiweyo. Gcwalisa i-oyile ngesithuba sezinyo esivulwe kwindawo yokufunxa i-oyile. I-oyile ithuthwa isuka kwindawo yokufunxa i-oyile (S) ukuya kwindawo yoxinzelelo (P) ngokucocwa kwecala phakathi kweshaft yegiya yangaphandle kunye neringi yegiya. Ngenxa yoko, ioli ikhutshwe kwi-gap yezinyo elivaliweyo kwaye ihanjiswe kwi-port yeoli yoxinzelelo (P). Indawo yokufunxa i-oyile kunye nendawo yokukhupha yahlulwe yinto yembuyekezo ye-radial (9 ukuya kwi-11) kunye ne-mesh ye-gear phakathi kwe-inner ring gear kunye ne-outer gear.

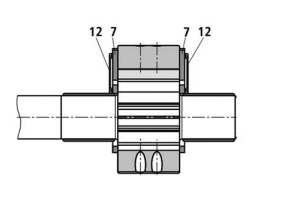

Imbuyekezo yeAxial

Igumbi lokukhupha kwindawo yoxinzelelo livalwe nge-axially nge-tge iuk ipleyiti yokusabalalisa (7). I-pan yokusabalalisa i-oyile ijongene kude nokukhutshwa kwelinye icala libuyele emva koxinzelelo olufakwe (12). Ezi nkalo zoxinzelelo zenza ipleyiti yokusabalalisa ioli kunye nommandla wokukhupha ufikelele kwi-balance, ukusuka kwisiphumo sokutywinwa esifanelekileyo sifezekiswa ngokulahleka okuphantsi komatshini.

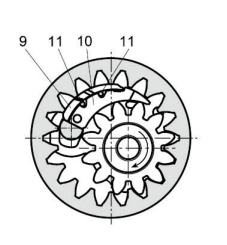

Imbuyekezo yeradial

I-radial compensation element ibandakanya i-crescent sub-plate (9), ipleyiti engundoqo yecrescent (10) kunye nentonga yokutywina (11). Ipleyiti engundoqo yecrescent (10) ukuya kumphezulu ongqukuva wencam yedokodo leshaft yegiya yangaphandle, icwecwe elisezantsi lecwecwe (9) lincanyathiselwe ngokusondeleyo kumphezulu wezinyo lencam yeringi yangaphakathi, kunye nentonga yokumisa. isetyenziselwa ukukhawulela ukuhamba kwecwecwe lecwecwe kwicala elijikelezayo.

Ngale ndlela, indawo yoxinzelelo inokwahlulwa kwindawo yokufunxa ngohlengahlengiso oluzenzekelayo lokucocwa. Oku yimfuneko yokugcina ukusebenza kwevolumetric ephezulu ngokuqhubekayo kuzo zonke iiyure zokusebenza.

Amazinyo

I-toothing ene-involute flanks ibonisa ubude obude be-meshing ukuhamba okuphantsi kunye noxinzelelo lwe-pulsation kwaye ngoko iqinisekisa ukusebenza kwengxolo ephantsi.

Ukutyunjwa koMfanekiso

| VG1 | -63 | R | E | W | -A1 |

| Uthotho | Ukufuduswa ml/r | Ukujikeleza | Uhlobo lweshaft | Izinto zokutywina | Inombolo yoyilo. |

| VG0 | 8, 10, 13, 16, 20, 25 | Iimbono ukusuka kwi-shaft ekupheleni kwempompo R= Isandla sasekunene kwi-clockwise L=Isandla sasekhohlo xa sijonga indlela yokuya ngasekunene | E=isitshixo esithe nkqo R=Spline shaft | W= NBR V=FKM | A1 |

| VG1 | 25, 32, 40, 50, 63, 50H, 63H | ||||

| VG2 | 80, 100, 125, 145, 160 |

Iishafu zokumpompa

Ukudibanisa impompo

Iimbono zendawo yokusebenza

Ulawulo lwe-6S

Isicelo

Ingasetyenziswa ngokubanzi kushishino, njengoomatshini beplastiki, umatshini wezihlangu, oomatshini bokuphosa ukufa kunye ne-forklift kunye namanye amashishini enkqubo ye-hydraulic, ngakumbi kwi-servo variable frequency drive system yokonga amandla.

Amanqaku okuqwalaselwa ukusetyenziswa

1. Ukufakwa kwempompo yeoli

- Kangangoko kunokwenzeka, ukudityaniswa okuguquguqukayo kusetyenziselwa ukudibanisa phakathi kwempompo yempompo kunye ne-motor shaft ukunqanda umzuzu wokugoba okanye i-axial thrust. Eyona mpazamo iphezulu evumelekileyo ye-coaxiality phakathi kwempompo shatf kunye ne-motor shaft yi-0.15mm.

2. Uqhagamshelo lokungena nokuphumayo

- Khetha i-diameter yangaphakathi yombhobho ngokwe-oyile ye-oyile yempompo ye-oyile (isantya esiphezulu sokungena yi-0.6-1.2m / s);

- Imilinganiselo yoyilo yomgca wetyhubhu yokufunxa kufuneka ihambelane noxinzelelo lokusebenza oluvunyiweyo lokungena (ixabiso elipheleleyo le-0.8bar ukuya kwi-2bar), kwaye kufuneka uphephe ukugoba umgca wetyhubhu yokufunxa kunye nendibaniselwano yetyhubhu yokufunxa impompo emininzi;

- Ukuba i-oyile yokufunxa i-fliter isetyenzisiweyo, kucetyiswa ukuba i-oyile yokufunxa i-oyile ikhethwe ngokuhambelana nokuhamba okuphezulu kwepompo yeoli, iphindwe yi-coefficient ye-2-3 amaxesha, kunye nokuchaneka okupheleleyo kokucoca yi-50-180um. Kufuneka kuqinisekiswe ukuba nokuba isihluzi singcolisekile, asiyi kudlula ubuncinci obuvumelekileyo boxinzelelo lokusebenza lwe-inlet yesixokelelwano;

- Ubunzulu bontywiliselo betyhubhu yokufunxa ekhethiweyo kufuneka bunzulu kangangoko. Imisinga ye-Eddy akufanele yenziwe nakwizinga eliphezulu lokuhamba, ngaphandle koko kuya kuba yingozi yokufunxa umoya kunye nokukhululwa.

- Kuyilo lombhobho wokufunxa, i-oyile yokungena ayikhuthazwa ukuba ifakwe ngokuthe nkqo phantsi. Ukuba itanki yeoli ifumaneka ngaphantsi kwempompo yeoli, i-oyile yokungena kufuneka ibe phezulu okanye kumacala omabini axwesileyo.

3. Indibaniselwano yempompo

- Xa udibanisa iimpompo, kuyimfuneko ukuqinisekisa ukuba isigaba ngasinye sihambelana nomhla ovumelekileyo wokusebenza weentlobo zempompo ezifanelekileyo;

- Isikhokelo sokujikeleza kuzo zonke iimpompo ezidibeneyo kufuneka zifane;

- Iimpompo ezinetorque ephezulu, ukufuduswa okuguquguqukayo okanye umthwalo osetyenzisiweyo uya kubonelela njengenqanaba lokuqala lempompo edibeneyo;

- Ubuninzi be-torque ye-shaft drive kufuneka ihlolwe ngumcwangcisi weprojekthi kwizicelo ezahlukeneyo.

Ubuninzi betorque evumelekileyo (Nm)

I-torque epheleleyo yepompo edibeneyo ayiyi kudlula i-torque ephezulu yokuqhuba.

Ukuphefumla okudityanisiweyo akuvumelekanga.

Uyilo lweshafu yempompo yangasemva kufuneka lube ngu "R" (i-spline).

4. Ukusebenza kokuqala

- Jonga ukuba ingaba inkqubo yolwelo lolwelo lwamanzi ifakwe kakuhle kwaye iqhagamshelwe ekuqaleni;

- Phambi kokuba usebenze, kufuneka ngetyhubhu yokufunxa okanye umzila ohambayo wangaphakathi uzaliswe yimpompo yeoli yehydrailic, ivalve yokukhulula ioyile, uvule inkqubo phantsi kwemeko yokungabikho kweenjini ezisebenzayo, hlala ngokwaneleyo impompo yeoli yokuthambisa, kwaye ukhuphe umoya kumbhobho (ioyile Ukungacwangciswa kwevalve yoncedo, njengenkqubo enokusebenzisa i-joint yokuthumela ngaphandle impompo kancinci, ezinye iindlela, zokukhupha igesi evuzayo Xa amaqamza engasabonakali kwi-oyile evuzayo, indawo ekhululweyo iya kutshixwa ngokwe torque echaziweyo : xa usebenzisa le ndlela, kufuneka ibe phantsi koxinzelelo oluphantsi kwaye uqinisekise ukuba uxinzelelo aluvuki.

- Ayikwazi ukuqala ukulayisha, ngaphandle koko kuya kubangela umonakalo wangaphakathi wempompo yeoli.

- Emva kokusebenza okuphindaphindiweyo kwamachaphaza, isandi sokufunxa siya kunyamalala. Ukuba isandi sokuxubana komoya asipheli emva kokuphinda-phinda ukusebenza kwamachaphaza amaxesha amaninzi. Kufuneka ukuba kukho ukuvuza komoya kumbhobho kwicala lokungena.

5. Isondlo

- Ukuze kuphuculwe ukunyuswa kwenkonzo yempompo yeoli, ukungcangcazela okungaqhelekanga, ingxolo, ubushushu be-oyile, imeko ye-oyile ye-hydraulic system, nokuba kukho amaqamza kwitanki nokuba kukho ukuvuza kunye nezinye iingxaki kufuneka zijongwe rhoqo kwaye zigcinwe ngaphakathi. ixesha;

- Zonke iimpompo zeoyile ziye zaluphumelela uvavanyo lokusebenza phambi kokuba zishiye umzi-mveliso. Naliphi na ishishini okanye umntu akayi kuqhawula, adibanise okanye aguqule iimpompo zeoyile ngaphandle kwemvume yenkampani. Ukuba uyaqhaqha, uphinde udibanise okanye uguqule iimpompo zeoyile ngaphandle kwemvume yenkampani, akukho ngaphakathi kwendawo yengxelo yokulungisa yenkampani kwaye inkampani ayiyi kuthatha naluphi na uxanduva.