The whole set of servo system naming rules

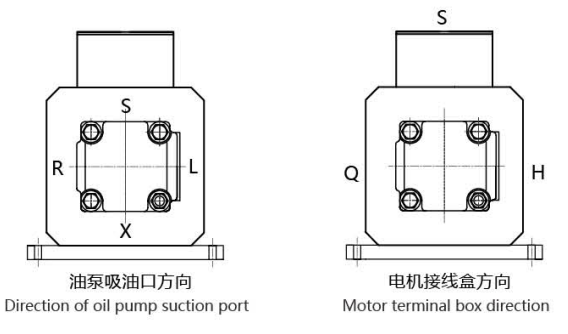

Direction of system assembly naming rules

The system direction is composed of two letters

The first letter represents the direction of the suction port of the oil pump

The second letter represents the direction of the motor junction box

Common system direction diagram

According to customer demand for supporting programs

| No. | Pump | Motor | Drive | Model No |

| 1 | VG gear pump | ABT servo motor | ABT servo drive | VG50-ABT1008F-ABT18.5KW-RS |

| 2 | VG gear pump | ABT servo motor | Delta servo drive | VG50-ABT1008F-Delta18.5KW-RS |

| 3 | VG gear pump | Hysis servo motor | Delta servo drive | VG50-U1008F-Delta18.5KW-RS |

| 4 | Sumitomo gear pump | Hysis servo motor | Delta servo drive | QT50-U1008F-Delta18.5KW-RS |

| 5 | Eckerle gear pump | Hysis servo motor | Delta servo drive | EIPC50-U1008F-Delta18.5KW-RS |

| 6 | ABT servo pump | Coaxial servo motor | ABT servo drive | ABT50-ABT1008T-ABT18.5KW-RS |

| 7 | ABT servo pump | Coaxial servo motor | Delta servo drive | ABT50-ABT1008T-Delta18.5KW-RS |

Remarks:

1. The order model takes the commonly use 50cc oil pump, matching 118.5kw motor and drive as an example.

2. For details of the coaxial motor servo system, please refer to the Vicks Coaxial Servo System catalogue.

Coaxial Servo System

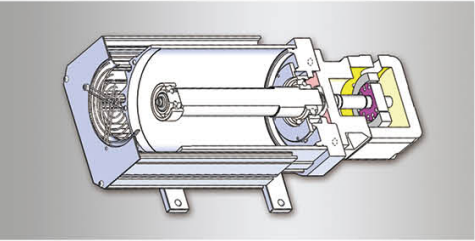

The coaxial structure is an upgrade made by Ningbo Vicks Hydraulic Co., Ltd. on the basis of the Haitian spline connection. It has the advantages of the spline structure and avoids the spline connection defect. For example, the grease at the spline joint is easy to dry after long-term use, and the splines of the oil pump and the motor directly collide positively and negatively to make tooth hitting, which causes the spline to slip. It is expensive to replace the oil pump and motor set. In the coaxial servo system, the motor and the oil pump share the same shaft, which can be cut by a single round after an integrated finishing process. To ensure the coaxiality, no grease is needed. The strength of the coaxial is higher up to 4 times the torque design, and the probability of shaft breakage is extremely low.

Section structure

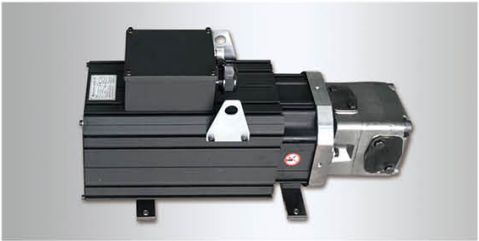

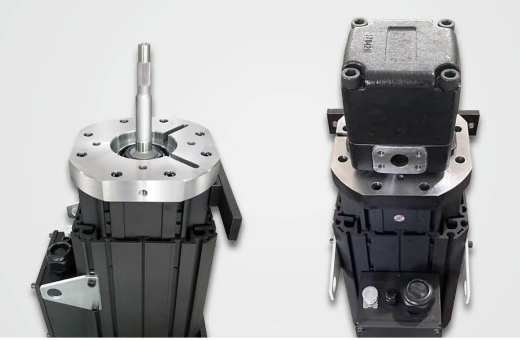

Physical drawing

Introduction to coaxial servo system

- On the basis of the existing servo oil pump and motor, changing the coupling mode makes a more energy saving, more stable and easier-to-use servo system solution.

- The coaxial servo system has the advantages of saving pump brackets, saving couplings, saving space, and better concentricity.

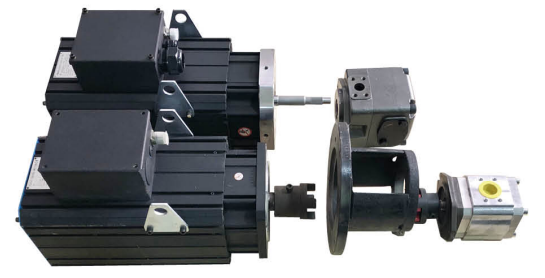

Compare with existing servo oil pump and motor

Coaxial Servo System Views

Main Features

1. Adopting axial and radial pressure compensation design, high volume efficiency.

2. Ultra-low noise, using high-strength cast iron and unique noise-absorbing design

3. Very low flow and pressure pulsation, maintainning stable flow and pressure output under low-speed working conditions.

4. High pressure design, the highest working pressure can reach 35Mpa.

5. Wide speed range, the highest speed can reach 300rpm.

6. It can be combined to form a double pump.

7. It is widely uesd in hydraulic machinery, such as injection molding machine, die-casting machine, hydraulic press and other servo hydraulic systems.

Main Features

1. Dowel pin type vane kits designation can make the pump with small resistance, low electronic, and with more energy saving.

2. Use outside leakage and leakage volume control designation low the oil temperature obviously. Based on the hydraulic componenets leakage volume, can adjust the oil leakage smartly, the pump pressure pulse is small at high pressure and low speed, the injection finished products will be more higher accuracy.

3. With the ccorodination of high pressure oil and vice spring structure, can make the pump run normally at low speed, can fit low and high speed shift, high and low pressure speed shift, right and left rotation shift etc working status of servo hydraulic system perfectly.

4. Double action and right-left rotation structure designation make the pump work more steadily, servo hydraulic system response more quickly.

5. High pressure, high speed structure and double cutting edges designation make the speed range more wide, and with more better polution resistance, and more longer working life.

6. Low noise structure designation and wide range of flow, can be customized according to different requirements.

7. Use the cartridge kit installation structure, repairing only need change the cartridge kit, more conveninet for repairing , and with more lower cost.

8. Double pump use one inlet port and two outlet ports, the structure is more compact with small installation space.

9. There are four directions each at inlet and outlet port, installtion is more flexible.

Features:

1. Subwoofer design: The unique linear conjugate internal meshing tooth profile avoids the influence of oil trapping and greatly reduces the noise and pressure pulsation of the pump. Especially when the pressure increases, the noise remains low.

2. Excellent durability: The use of special materials and processing technology, so that the life of pump is longer too.

3. Low pulsation: almost no pulsation, suitable for systems that require precise speed control.

Made in Germany, after nearly half a century of development and continuoous improvement, it has the advantages of high pressure, low noise, low pulsation and light weight. It is widely used in injection machines, die casting machines, hydraulic presses and other global hydraulic machinery.

Albert Servo Drive

Albert Servo Motor