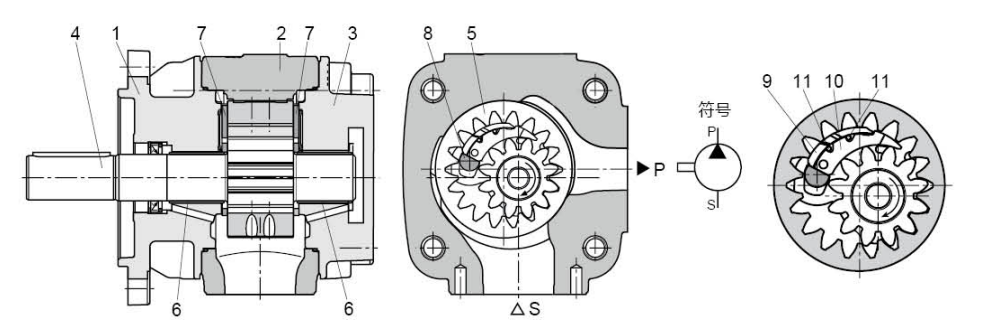

Priciple Diagram yeGear Pombi

TheVG hydraulic pombindeye backlash muripo wemukati giya pombi ine akutama kwakagadziriswa. Chimiro chayo chakakosha ndeichi: intall yekumberi chivharo (1), pombi muviri (2), yekumashure chivharo (3), yekunze giya shaft (4), yemukati giya mhete (5), inotsvedza (6), ndiro yekugovera mafuta (7) , uye tsvimbo yekumisikidza(8), inoumbwa necrescent sub-board (9), crescent main board (10) netsvimbo yekuisa chisimbiso (11)

Kusveta uye spiling maitiro

Iyo yekunze giya shaft (4) yakaiswa zvinoenderana nemagetsi emagetsi inotyaira yemukati giya mhete (5) munzira yekutenderera inoratidzwa. Zadza mafuta kuburikidza nemukaha wemazino wakavhurwa munzvimbo yekusveta mafuta. Oiri inotakurwa kubva kunzvimbo yekukweva oiri (S) kuenda kunzvimbo yekumanikidza (P) kuburikidza nedivi rekuchenesa pakati pekunze giya shaft uye inter gear ring. Nekuda kweizvozvo, mafuta anoburitswa kubva pakavharwa zino gap uye anounzwa kune anomanikidza mafuta port (P). Nzvimbo yekusveta mafuta uye nzvimbo yekuburitsa inoparadzaniswa neiyo radial compensation element (9 kusvika 11) uye giya mesh pakati pemukati memukati mhete giya uye yekunze giya.

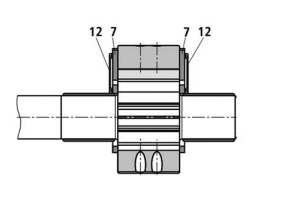

Axial compension

Iyo yekuburitsa kamuri munzvimbo yekumanikidza inonamirwa axially netge iuk yekugovera ndiro (7). Iyo pani yekugovera mafuta yakatarisana kure nekubuda, rimwe divi rakadzoserwa nekumanikidzwa kwakaiswa (12). Iyi minda yekumanikidza inoita kuti ndiro yekugovera oiri uye nzvimbo yekuburitsa isvike pachiyero, kubva kune yakanakira yekuisa chisimbiso mhedzisiro inowanikwa nekuderera kwemechani kurasikirwa.

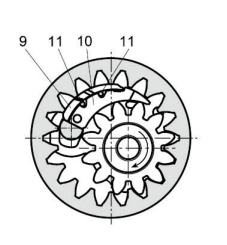

Radial compensation

Iyo radial compensation element inosanganisira crescent sub-plate (9), crescent main plate (10) uye tsvimbo yekuisa chisimbiso (11). Iyo crescent main plate (10) kune yakatenderedza pamusoro pedumba rekunze rekunze giya shaft, iyo crescent sub-plate (9) yakanyatsobatanidzwa kune yakatenderedza pamusoro peziso rezino remhete yemukati yegiya, uye tsvimbo yekumisikidza. inoshandiswa kudzikamisa kufamba kwecrescent plate munzira yekutenderera.

Nenzira iyi, nzvimbo yekumanikidza inogona kupatsanurwa kubva kunzvimbo yekukwevera nekugadziriswa otomatiki clearance. Ichi chinhu chinodiwa kuchengetedza yakakwira volumetric effeciency nguva dzose mukati memaawa ekushanda.

Toothing

Iyo zino ine involute flanks inoratidzira kureba meshing kureba kwekuyerera kwakaderera uye kudzvanywa pulsation uye nekudaro inovimbisa yakaderera ruzha kushanda.

Model Designation

| VG1 | -63 | R | E | W | -A1 |

| Series | Displacement ml/r | Kutenderera | Shaft type | Kuisa chisimbiso | Dhizaini Nha. |

| VG0 | 8, 10, 13, 16, 20, 25 | Maonero kubva kumucheto wepombi R= Ruoko rworudyi rwekuchinjika wachi L=Ruoko rworuboshwe rwekupikisa-wachi | E=yakatwasuka kiyi shaft R=Spline shaft | W= NBR V=FKM | A1 |

| VG1 | 25, 32, 40, 50, 63, 50H, 63H | ||||

| VG2 | 80, 100, 125, 145, 160 |

Migero yepombi

Kuunganidza pombi

Maonero epabasa

6S Management

Application

Inogona kushandiswa zvakanyanya muindasitiri, senge epurasitiki muchina, shangu muchina, kufa kukandira muchina uye forklift uye mamwe maindasitiri hydraulic system, kunyanya ye servo inosiyana frequency drive simba rekuchengetedza system.

Pfungwa dzekutarisa kushandisa

1. Kuiswa kwepombi yemafuta

- Sezvinogoneka, kubatanidza kunochinjika kunoshandiswa kubatanidza pakati pepombi shaft uye mota shaft kudzivirira nguva yekukotama kana axial thrust. Iyo yakanyanya kubvumidzwa coaxiality kukanganisa pakati pepombi shatf uye mota shaft ndeye 0.15mm.

2. Inlet uye kubuda kwekubatanidza

- Sarudza dhayamita yemukati yepombi zvinoenderana nechiteshi chemafuta chepombi yemafuta (iyo yakakwana inlet velocity ndeye 0.6-1.2m / s);

- Iwo madhizaini emutsetse wekusveta tubing anofanirwa kuenderana neinobvumidzwa inlet kushanda kumanikidza (yakazara kukosha kwe0.8bar kusvika 2bar), uye inofanirwa kudzivirira kupeta tambo yekukweva tubing uye musanganiswa wepombi yekusveta tubing akati wandei;

- Kana iyo mafuta ekusveta fliter yakashandiswa, zvinokurudzirwa kuti mafuta ekusveta sefa asarudzwe zvichienderana nekuwanda kwekuyerera kwepombi yemafuta, yakapetwa neiyo coefficient ye 2-3 nguva, uye iyo yakakwana yekusefa kurongeka ndeye 50-180um. Inofanirwa kuve nechokwadi chekuti kunyangwe iyo sefa yakasvibiswa, haipfuure iyo yakaderera inotenderwa inlet kushanda kumanikidza kweiyo system;

- Kunyudza kudzika kwechubhu yekukweva kwakasarudzwa kunofanirwa kunge kwakadzika sezvinobvira. Eddy currents haifanirwe kuumbwa kunyangwe pahupamhi hwekuyerera, kana zvisina kudaro ichava njodzi yekusvetwa kwemhepo uye kusunungurwa.

- Mukugadzirwa kwepombi yekukwevera, iyo inopinza mafuta haikurudzirwe kuti iiswe yakatwasuka pasi. Kana tangi yemafuta iri pazasi pepombi yemafuta, iyo inopinza mafuta inofanira kunge iri kumusoro kana mativi ese akatwasuka.

3. Kusanganiswa kwepombi

- Paunenge uchibatanidza mapombi, zvinodikanwa kuve nechokwadi kuti nhanho imwe neimwe inoenderana neinobvumidzwa zuva rekushanda remhando dzepombi dzakakodzera;

- Nzira yekutenderera yemapombi ose akabatanidzwa inofanira kunge yakafanana;

- Mapombi ane torque yakakura, kuchinjika kuchinjika kana kuisirwa mutoro unopihwa sechikamu chekutanga chepombi yakasanganiswa;

- Maximum shaft drive torque inofanirwa kuongororwa nemurongi weprojekiti kune akasiyana maapplication.

Maxmum inotenderwa torque (Nm)

Iyo yakazara torque yepombi yakasanganiswa haifaniri kudarika iyo yakanyanya kutyaira torque.

Combination inhalation haibvumirwi.

Rear pombi shaft dhizaini inofanira kunge iri "R" (spline).

4. Kushanda kwekutanga

- Tarisa uone kana iyo hydraulic system yakaiswa zvakanaka uye yakabatana pakutanga kwekutanga;

- Usati washanda, unofanirwa kuburikidza nekuyamwa tubing kana kuyerera kwemukati yakazadzwa nehydrailic pombi yemafuta, vharafu yekuyamura mafuta, kuvhura sisitimu pasi pemamiriro ekusatakura mota dzinoshanda, gara wakakwana pombi yemafuta ekuzora, uye kuburitsa mweya mupombi (mafuta ari kwete kuseta vharafu yekuyamura, senge system inogona kushandisa iyo pombi ekisipoti yekubatanidza zorora zvishoma, dzimwe nzira, yekuburitsa gasi inodonha Kana mabhubhu asingachaoneki mumafuta akadonha, chikamu chakasunungurwa chichava yakakiyiwa zvinoenderana ne torque yakataurwa: kana uchishandisa nzira iyi, inofanirwa ne pasi pekumanikidzwa kwakaderera uye kuve nechokwadi chekuti te predsure haisimuke.

- Kusakwanisa kutanga kurodha, zvikasadaro zvinokonzeresa kukuvara kwemukati pombi yemafuta.

- Mushure mekudzokorora kuvhiyiwa kwedonhwe, ruzha rwekusveta rwunopera. Kana mhepo yekusanganisa ruzha ikasanyangarika mushure mekudzokororwa dot kushanda kwekakati wandei. Panofanira kunge paine kubuda kwemhepo mupombi padivi rekupinza.

5. Kuchengeta

- Kuti uvandudze kusimudzwa kwesevhisi yepombi yemafuta, kuzunguzika kusingaite, ruzha, tembiricha yemafuta, mamiriro emafuta eiyo hydraulic system, kana paine mabhuru mutangi uye kana paine kuvuza uye mamwe matambudziko anofanirwa kuongororwa nguva nenguva uye kuchengetedzwa mukati. nguva;

- Mapombi emafuta ese akapasa bvunzo dzekushanda asati abuda mufekitari. Chero bhizinesi kana munhu haafanire kuparadzanisa, kuunganidzazve kana kushandura pombi dzemafuta pasina mvumo yekambani. Kana ikaparadzana, ikaunganidzazve kana kushandura pombi dzemafuta pasina mvumo yekambani, haisi mukati mechikamu chemushumo wekambani yekugadzirisa uye kambani haifanire kutora chero basa.