Vane pumps often fail due to contamination, wear, and insufficient maintenance. Solid particles in hydraulic fluids cause abrasion on vanes and stators, leading to premature wear. Regular maintenance, including timely vane replacement and filter cleaning, prevents costly repairs. Studies confirm that proper care can extend the lifespan of vane pumps by up to 40%.

Key Takeaways

- Doing regular checkups and changing old parts on time helps vane pumps last 40% longer.

- Using high-quality hydraulic oils makes pumps work better and stops sludge from forming.

- Cleaning often and using good filters keeps dirt out and lowers repair costs.

Common Causes of Vane Pump Failures

Wear and Tear

Wear and tear remain one of the most common reasons for vane pump failures. Over time, components such as vanes, seals, and rotor surfaces degrade due to friction and cavitation. Grinding or whining noises often indicate misaligned or worn-out parts. Pressure readings that show a significant drop can signal internal leaks caused by damaged seals. Regular inspections and timely replacement of worn components are essential to maintain optimal performance.

| Indicator | Description |

|---|---|

| Grinding or whining noises | Suggests worn-out or misaligned parts. |

| Pressure readings | Significant loss indicates internal leaks from worn vanes or damaged seals. |

| Fluctuations in flow rate | Often indicates pump cavitation or obstructions. |

| Visual inspections | Can reveal leakage, corrosion, or material degradation. |

Contaminated Hydraulic Fluids

Contaminated hydraulic fluids introduce solid particles, water, and chemical impurities into the system, causing significant damage. Dirt and metallic shavings wear down pump components, while water contamination reduces lubrication effectiveness and corrodes metal surfaces. Chemical impurities can form sludge and varnish, blocking passages and reducing efficiency. Installing effective filtration systems and monitoring fluid quality can mitigate these risks.

Improper Installation

Improper installation procedures often lead to misalignment and operational inefficiencies. Ensuring correct installation practices, such as aligning components and verifying fluid compatibility, prevents premature failures. Regular checks of installation quality further enhance reliability.

Overheating

Overheating occurs when vane pumps operate beyond their designed capacity or experience inadequate fluid flow. Excessive pressure and blockages in hydraulic lines increase friction and fluid shear, leading to high temperatures. Monitoring system temperature and adhering to load limits are crucial to prevent overheating-related failures.

Lack of Maintenance

Neglecting maintenance routines accelerates wear and increases the risk of unexpected breakdowns. Properly maintained vane pumps can last between 6 to 9 years or 12,000 to 18,000 hours. Implementing a comprehensive maintenance schedule ensures longevity and reduces downtime.

Operating Beyond Limits

Operating vane pumps beyond their design limits places excessive stress on components, accelerating wear and reducing efficiency. Adhering to recommended operating parameters and managing pressure and flow control effectively minimizes the risk of failure.

7 Maintenance Hacks to Extend Lifespan by 40%

Use Premium Hydraulic Fluids

Premium hydraulic fluids significantly enhance the performance and lifespan of vane pumps. These fluids exhibit superior hydrolytic stability, oxidation resistance, and thermal stability, ensuring reliable operation under demanding conditions. They also prevent sludge formation, maintain demulsibility, and provide effective rust protection. For instance:

- Hydrolytic Stability Tests: Weight loss remains below 0.2 mg/cm², preventing sludge and acidity formation.

- Oxidation Life: Extended even after rigorous pump testing, ensuring long-term efficiency.

- Denison Filterability Tests: Performance retention under dry and wet conditions reduces filter blockages.

Using premium fluids ensures clean systems, reduces wear, and minimizes maintenance issues, making them a vital investment for longevity.

Maintain a Cleaning Routine

A consistent cleaning routine prevents contaminants from damaging internal components. Dirt, water, and metallic particles can cause abrasion, corrosion, and blockages. Cleaning and replacing filters regularly ensures efficient operation and prevents costly repairs. According to maintenance standards, this practice alone can extend the expected lifespan of vane pumps to 6–9 years or 12,000–18,000 hours.

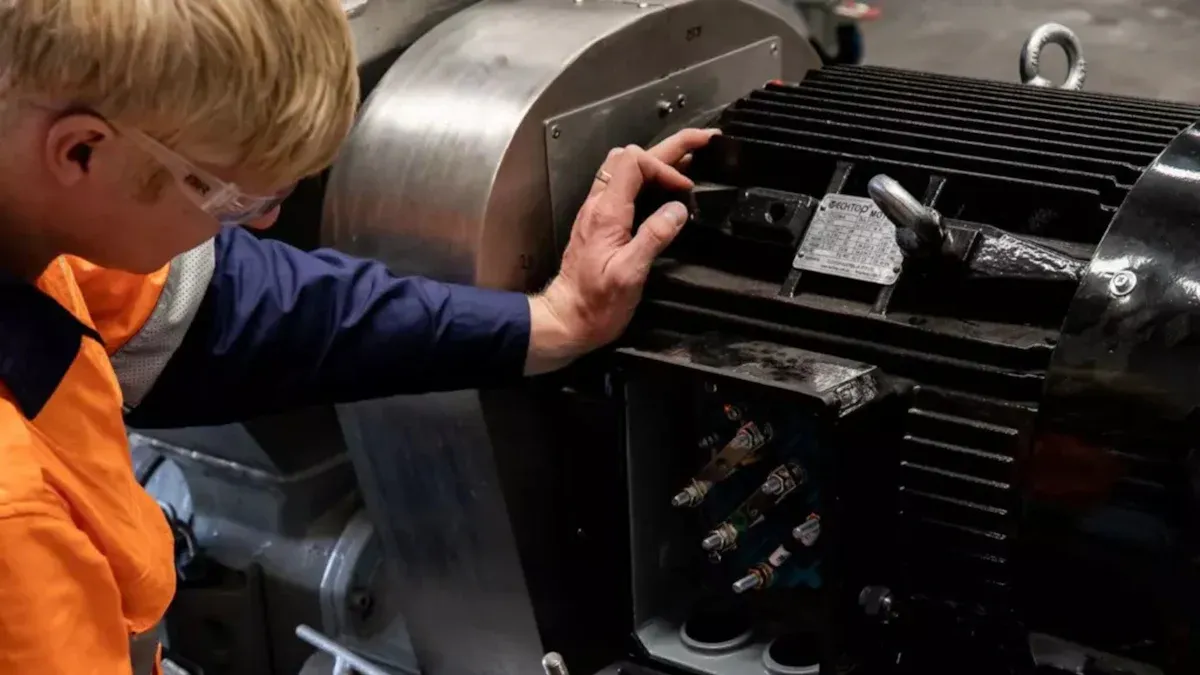

Replace Worn Parts Regularly

Timely replacement of worn parts, such as vanes and seals, prevents further damage and maintains efficiency. Grinding noises or pressure drops often indicate wear. Addressing these issues promptly avoids internal leaks and ensures smooth operation.

Ensure Correct Installation

Proper installation minimizes failure rates. Monitoring operational parameters like temperature, flow rate, and pressure prevents cavitation. Additionally, ensuring fluid compatibility and avoiding sharp bends in suction lines reduces stress on components. These practices enhance reliability and operational efficiency.

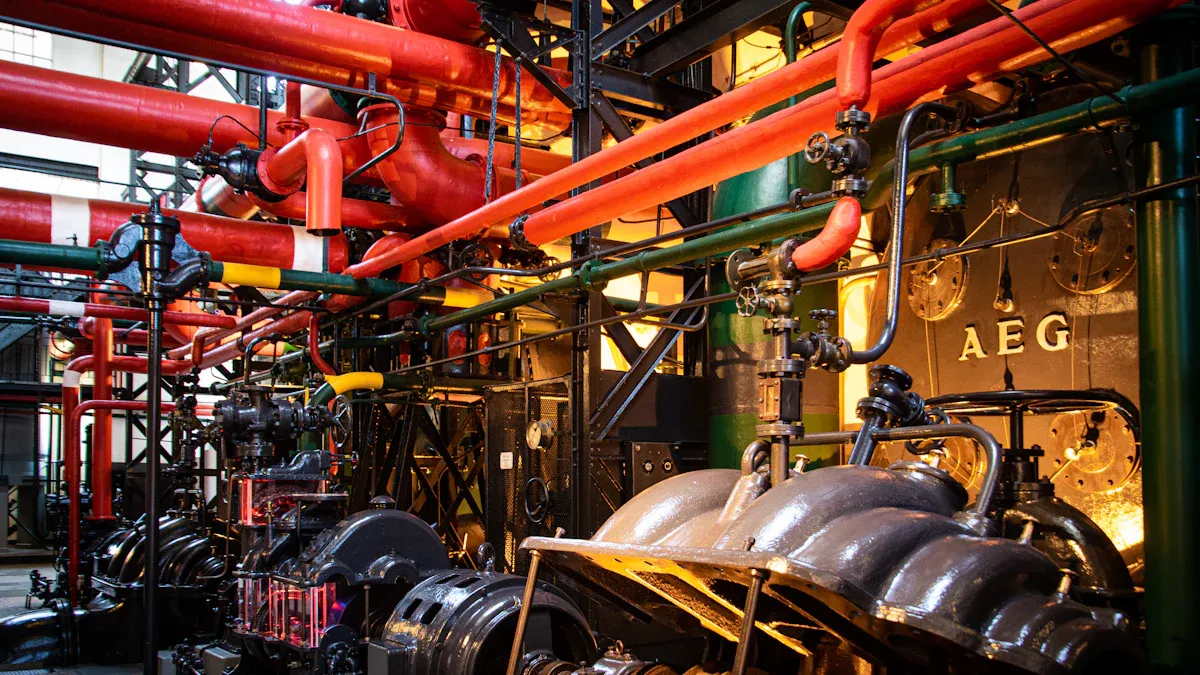

Install Effective Filtration Systems

High-efficiency filtration systems protect vane pumps from contaminants. Filters with beta ratios above 75 effectively remove particles larger than ten microns, reducing wear and heat generation. Regular fluid analysis and adherence to ISO 4406 cleanliness standards ensure optimal performance and longevity.

Avoid Overloading

Operating vane pumps within their design limits prevents premature failures. Overloading increases stress on components, accelerating wear and reducing efficiency. Proper system design and adherence to operating parameters are essential for long-term reliability.

Schedule Routine Inspections

Routine inspections identify potential issues early, preventing unexpected breakdowns. Regular checks of pressure readings, fluid quality, and component wear ensure consistent performance. A proactive approach to maintenance reduces downtime and extends the lifespan of vane pumps.

Monitoring and Troubleshooting Vane Pumps

Identifying Early Failure Signs

Detecting early warning signs of vane pump issues prevents costly repairs and downtime. Operators should monitor key indicators to identify potential problems before they escalate. Common signs include:

| Indicator | Description |

|---|---|

| Unusual noises | Sounds like rattling or grinding may indicate mechanical faults. |

| Pressure fluctuations | Low system pressure can suggest significant wear or internal leakages. |

| Temperature changes | Elevated temperatures may indicate poor lubrication due to component damage. |

| Visual inspections | Observing leaks or wear around the pump body or connections can signal sealing issues. |

| Vibration patterns | Peculiar vibrations can imply mechanical issues or cavitation phenomena. |

Regular monitoring of these indicators ensures timely intervention, reducing the risk of complete pump failure.

Tools for Performance Monitoring

Advanced tools enhance the ability to monitor vane pump performance effectively. These tools include:

- Vibration analysis: Measures frequency and amplitude to detect imbalances or wear.

- Pressure testing: Uses calibrated gauges to identify blockages or leaks.

- Flow measurement: Compares actual flow rates with design specifications to detect cavitation or inefficiencies.

Incorporating predictive analytics software further improves maintenance planning by forecasting potential failures based on operational trends.

Troubleshooting Techniques

When issues arise, systematic troubleshooting ensures accurate diagnosis and resolution. Common methodologies include:

| Methodology | Description |

|---|---|

| Vibration Analysis | Measures frequency and amplitude of vibrations to identify imbalances, misalignment, or wear. |

| Pressure Testing | Uses calibrated gauges to monitor pressure drops, indicating blockages or leaks in the system. |

| Flow Measurement | Assesses actual flow rate against design specifications to identify performance issues like cavitation. |

Combining these techniques with operational data provides a comprehensive understanding of the problem, enabling precise corrective actions.

When to Seek Professional Help

Certain situations require expert intervention to avoid further damage. Persistent issues such as recurring leaks, severe pressure drops, or abnormal vibrations often indicate underlying problems that need specialized attention. Professionals possess the expertise and tools to conduct in-depth diagnostics and implement advanced repairs. Seeking help promptly ensures the longevity and reliability of vane pumps.

Proper maintenance and monitoring strategies prevent vane pump failures and enhance reliability. Regular inspections and predictive maintenance identify issues early, reducing downtime and repair costs. Advanced tools, such as sensors and analytics, optimize performance by tracking critical parameters. Implementing the seven maintenance hacks extends the lifespan of vane pumps by up to 40%, ensuring consistent operation and reduced risks.

FAQ

What are the signs of vane pump cavitation?

Cavitation often causes unusual noises, such as rattling or knocking, along with reduced flow rates and visible damage to internal components during inspections.

How often should hydraulic fluid filters be replaced?

Replace hydraulic fluid filters every 500–1,000 operating hours or as recommended by the manufacturer to maintain optimal system cleanliness and performance.

Can vane pumps handle high-pressure applications?

Yes, vane pumps can handle high-pressure applications when designed for such conditions. Models like the 35Mpa ultra-high-pressure vane pump excel in demanding environments.

Post time: Mar-21-2025