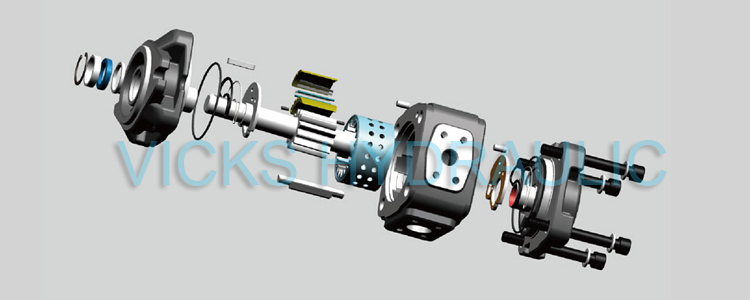

Manufacturing Companies for China Qt Hydraulic Rotary Gear Oil Pump for Injection Molding Machine Servo System

We attempt for excellence, company the customers”, hopes to be the top cooperation team and dominator company for personnel, suppliers and customers, realizes price share and continual marketing for Manufacturing Companies for China Qt Hydraulic Rotary Gear Oil Pump for Injection Molding Machine Servo System, Let’s cooperate hand in hand to jointly make a beautiful future. We sincerely welcome you to visit our company or contact us for cooperation!

We attempt for excellence, company the customers”, hopes to be the top cooperation team and dominator company for personnel, suppliers and customers, realizes price share and continual marketing for China Internal Gear Pump, Injection Molding Machines Servo Oil Pump, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we have been sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

Our company

Our company is general channel business of Taiwan Delta, Austria KEBA

product industry. Its the strategic partner of Phase servo motor,

Yunshen servo motor, Haitain drive and Sumitomo pump.

Ningbo Vicks adhering to the development path of introduction, innovation and

transcendence, and the business philosophy of high quality, high

efficiency, low consumption, safety. Our company has became a

world-renowned hydraulic pump manufacturer and one-stop solution expert

of servo energy saving.

Model Designation

| VG1 |

-63 |

R |

E |

W |

A1 |

| Series No |

Displacement |

Rotation |

Shaft type |

Sealing level |

Design No. |

| VG0 |

8,10,13,16,20 |

View from shaft end of pump R= right hand for clockwise L= left hand for count-clockwise |

E= Str Key R=SEA Spline |

W=NBR, Nitrile rubber, V=Fluororubber |

A1 |

| VG1 |

25,32,40,50,63 |

||||

| VG2 |

80,100,125,145,160 |

VG1 Series Internal Gear Pump Widely Used for Injection Machine

Main Features:

1. Using axial and radial pressure compensation design, even at low speed and low viscosity still maintain high volume efficiency.

2. Ultra-low noise, high strength cast iron and unique internal muffler design make the noise even lower

3. Extremely low flow and pressure pulsation, can maintain stable flow and pressure output at low speed condition.

4. High pressure design, the maximum working pressure can reach to 35Mpa.

5. Wide speed range, the highest speed up to 3000rpm/min.

6. Can be arbitrarily combined to form a double pump.

7. It is not sensitive to oil pollution and has long service life.

8. It can be widely used in industry, such as plastic machine, shoe machine, die casting machinery and forklift and other industries hydraulic system, especially for servo variable frequency drive energy saving system.

More pics

Advanced Equipment

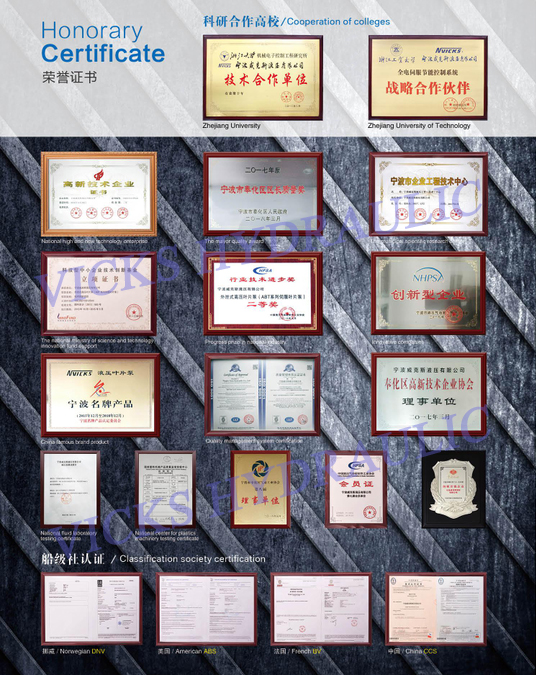

Certificate

Exhibition Shows

Our Services

RFQ

Q1. Can I get 1pcs for a try?

A: Yes, of course.

Q2: How can I place an order?

A: You can email us or send us an inquiry.

Q3: Have you checked the products before shipping?

A: Absolutely, yes. We tested it after assembling.

Q4: How many days for delivery ?

A: 3-7days in stock, 15-25days for large cargo.

Q5: How many months for warranty?

A: Ordinary speaking, we can gurantee 12 months with your correct operation.

Q6: Can I use our Logo?

A: No problem.