Hot Selling for China Vickers Hydraulic Vane Pump with Variable Displacement

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Hot Selling for China Vickers Hydraulic Vane Pump with Variable Displacement, We welcome you to join us within this route of creating a affluent and productive company with each other.

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for China Vicker Pump, Vane Pump, Our items are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Product Introduction

The High-pressure and high-performance Intra-vane pumps for Mobile Equipmen

Features

1.To adopt balanced hydraulic for the structure of Intra-vane and ten –Vane design, higher pressure, top to 21 MPa.

2.To adopt floating structure for side plate, it will do a compensation for end-face clearance by automatic, so that even the pump under high pressure it can maintain a high volumetric efficiency.

3.The side plate is made of dual-metal material, it improved the seizure resistance, and so that the life of pump will be longer.

Our company

Our company is general channel business of Taiwan Delta, Austria KEBA product industry. Its the strategic partner of Phase servo motor,Yunshen servo motor, Haitain drive and Sumitomo pump.

Ningbo Vicks adhering to the development path of introduction, innovation and transcendence, and the business philosophy of high quality, high efficiency, low consumption, safety. Our company has became a world-renowned hydraulic pump manufacturer and one-stop solution expert of servo energy saving.

VQ Series Double Pump

| NO. | Part | Qty | NO. | Part | Qty | NO. | Part | Qty |

| 1 | Straight Key | 1 | 7 | Cir Clip For Shaft | 1 | 13 | Rear Cartridge | 1 |

| 2 | Shaft | 1 | 8 | Pile Type Retainer | 1 | 14 | O Ring | 1 |

| 3 | Front Cover | 1 | 9 | O Ring | 1 | 15 | Rear Cartridge | 1 |

| 4 | Shaft Seal | 1 | 10 | Front Cartridge | 1 | 16 | Hexagon Headed Bolt | 4 |

| 5 | Gasket | 1 | 11 | Body | 1 | |||

| 6 | Ball Bearing | 1 | 12 | Hexagon Headed Bolt | 4 |

Model Designation

| (F3-) | 3525V | 38 | A | 17 | -1 | AB | 22 | R |

| Note | Series | ▼ Flow-Shaft end pump | Port connection |

▼ Flow-cover

end pump |

Shaft type | Outlet Position |

Design number |

Rotation |

| No-marking:

Petroleum series oil emulsification fluid water glycol-fluid phosphate |

2520V | 10、12、14、15、17、 19、21、25 |

A-SAE A-SAE 4-bolt flange |

2、3、4、5、6、7、8、9、10、11、12、14 | 1-Str key 86-HD Str key 11-Spline |

See below | 22 | (Views from shaft end of pump) R-right hand for clockwise L-left hand for counter-clockwise |

| 3520V | 21、25、30、32、35、 38、45 |

2、3、4、5、6、7、8、9、10、11、12、14 | ||||||

| 3525V | 21、25、30、32、35、 38、45 |

10、12、14、15、17、19、21、25 | ||||||

| 4520V | 42、45、50、57、60、 66、75 |

2、3、4、5、6、7、8、9、10、11、12、14 | ||||||

| 4525V | 42、45、50、57、60、 66、75 |

10、12、14、15、17、19、21、25 | ||||||

| 4535V | 42、45、50、57、60、 66、75 |

21、25、30、32、35、38、45 |

▽Usgpm Flow(Usgpm) at 1200r/min and 0.69MPa

| Outlet Positions (Viewed from cover end of pump) | |||

| Outlet positions | All series except 4535V | 4535V | |

| No. 1 outlet opposite inlet | AA | No. 2 outlet 135° CCW from inlet | No. 2 outlet opposite inlet |

| AB | No. 2 outlet 45° CCW from inlet | No. 2 outlet 90° CCW from inlet | |

| AC | No. 2 outlet 45° CW from inlet | No. 2 outlet inline with inlet | |

| AD | No. 2 outlet 135° CW from inlet | No. 2 outlet 90° CW from inlet | |

| No. 1 outlet 90° CCW from inlet | BA | No. 2 outlet 135° CCW from inlet | No. 2 outlet opposite inlet |

| BB | No. 2 outlet 45° CCW from inlet | No. 2 outlet 90° CCW from inlet | |

| BC | No. 2 outlet 45° CW from inlet | No. 2 outlet inline with inlet | |

| BD | No. 2 outlet 135° CW from inlet | No. 2 outlet 90° CW from inlet | |

| Outlet positions | All series except 4535V | 4535V | |

| No. 1 outlet inline with inlet | CA | No. 2 outlet 135° CCW from inlet | No. 2 outlet opposite inlet |

| CB | No. 2 outlet 45° CCW from inlet | No. 2 outlet 90° CCW from inlet | |

| CC | No. 2 outlet 45° CW from inlet | No. 2 outlet inline with inlet | |

| CD | No. 2 outlet 135° CW from inlet | No. 2 outlet 90° CW from inlet | |

| No. 1 outlet 90° CW from inlet | DA | No. 2 outlet 135° CCW from inlet | No. 2 outlet opposite inlet |

| DB | No. 2 outlet 45° CCW from inlet | No. 2 outlet 90° CCW from inlet | |

| DC | No. 2 outlet 45° CW from inlet | No. 2 outlet inline with inlet | |

| DD | No. 2 outlet 135° CW from inlet | No. 2 outlet 90° CW from inlet | |

More pics

Application

Advanced Equipment

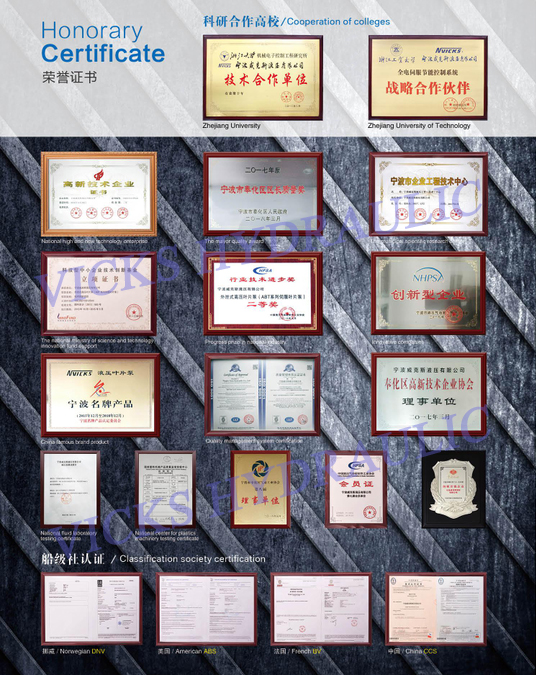

Certificate

Our services

RFQ

1. Customer: Can I get 1pcs sample to test the quality?

Vicks Hydraulic: Yes, we would like to sell 1pcs sample for you to test.

2. Customer: If there is something technical problem, how do you to help us.

Vicks Hydraulic: we will send you video and operations guide, which we will teach you to understand how to solve it.

3. Customer: How many days for mass production?

Vicks Hydraulic: About 25-35days after the order is confirmed.

VICKS HYDRAULIC