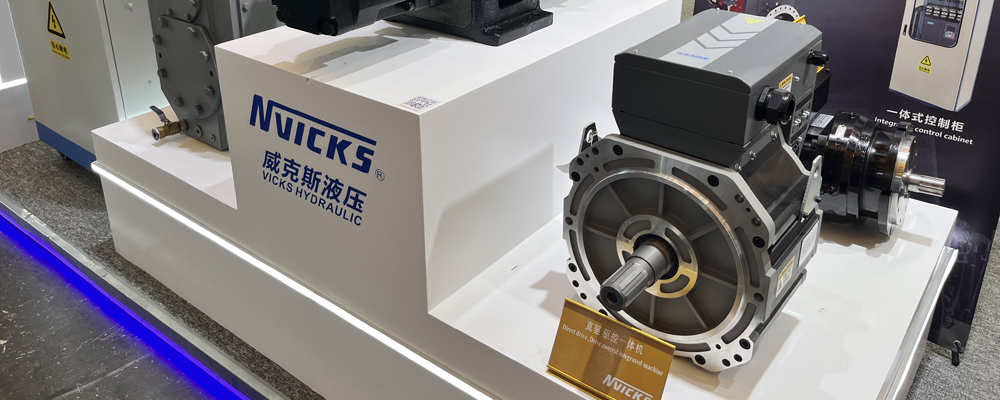

Qhia peb cov kev hloov pauv hluav taws xob Pre Molding System, tsim los coj koj cov txheej txheem yas molding mus rau qib tom ntej. Qhov kev txiav-ntug no tau nruab nrog lub zog siab hluav taws xob ua ntej molding motors, teeb tsa tus qauv tshiab rau kev siv hluav taws xob thiab kev ua haujlwm hauv kev lag luam.

Ib qho txiaj ntsig tseem ceeb ntawm peb Cov Hluav Taws Xob Pre Molding System yog nws lub peev xwm txuag hluav taws xob zoo kawg. Nrog lub peev xwm txuag 10% mus rau 25% ntau lub zog piv rau cov tsoos roj lub cev ua ntej molding tshuab, lub tshuab tshiab no tsis yog tsuas yog txo cov nqi ua haujlwm xwb tab sis kuj tseem ua rau muaj kev lag luam zoo dua qub thiab ib puag ncig zoo.

Lub siab torque hluav taws xob ua ntej molding motors yog engineered kom khiav tsis tu ncua thiab tsis tu ncua, xa ib tug ntau ruaj khov thiab npaum plasticizing nyhuv. Qhov no ua rau cov khoom zoo tshaj plaws thiab sib xws, muab kev ntseeg siab rau txhua qhov molded raws li cov qauv siab tshaj plaws.

Ntxiv rau nws cov txiaj ntsig kev siv hluav taws xob thiab kev ua haujlwm tau zoo, peb Cov Hluav Taws Xob Pre Molding System muaj kev ua haujlwm zoo dua qub thiab ua haujlwm yooj yim. Cov motors pab kom seamless synchronization rau qhib thiab kaw, streamlining lub voj voog tsim thiab txo lub sij hawm ntau lawm. Qhov no txhais tau tias koj tuaj yeem ua tiav cov txiaj ntsig ntau dua thiab ua kom muaj txiaj ntsig zoo tshaj plaws ntawm koj cov haujlwm tsim khoom.

Tsis tas li ntawd, cov hluav taws xob ua ntej molding motors muab qhov chaw ua haujlwm ntsiag to thiab huv dua piv rau cov tshuab roj twj tso kua mis, ua rau muaj kev zoo siab thiab ruaj khov rau koj cov neeg ua haujlwm.

Nrog nws cov thev naus laus zis siab tshaj thiab muaj peev xwm zoo dua, peb Cov Hluav Taws Xob Pre Molding System yog qhov kev xaiv zoo tshaj plaws rau cov tuam txhab nrhiav kom zoo dua lawv cov txheej txheem yas molding. Txawm hais tias koj tab tom tsim cov khoom me me lossis cov khoom lag luam loj, qhov system no yog tsim los ua kom tau raws li qhov xav tau ntawm kev tsim khoom niaj hnub no thiab xa cov txiaj ntsig tshwj xeeb.

Hauv kev xaus, peb Cov Hluav Taws Xob Pre Molding System sawv cev rau kev dhia mus rau hauv kev siv tshuab yas molding, muab kev siv zog tsis sib xws, kev ua haujlwm, thiab kev ua haujlwm yooj yim. Los ntawm kev nqis peev hauv cov txheej txheem tshiab no, koj tuaj yeem txhawb koj lub peev xwm tsim khoom, txo cov nqi, thiab pab txhawb rau yav tom ntej. Muaj kev paub lub zog ntawm hluav taws xob ua ntej molding thiab qhib qhov muaj peev xwm tshiab rau koj cov txheej txheem ntau lawm.

Post lub sij hawm: Apr-01-2024