Ƙa'idar Ƙa'idar Famfu na Gear

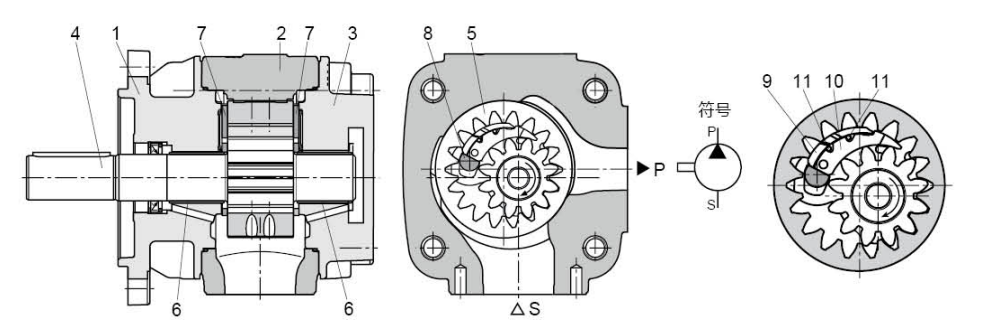

TheVG na'ura mai aiki da karfin ruwa famfoshine ramuwa na baya-bayan nan na cikin gida tare da aƙayyadaddun ƙaura. Tsarinsa na asali shine: murfin gaba (1), jikin famfo (2), murfin baya (3), shaft na gear waje (4), zoben gear na ciki (5), ɗaukar hoto (6), farantin rarraba mai (7) , da sandar sakawa (8), wanda ya ƙunshi ƙaramin allo (9), babban allo (10) da sandar hatimi (11)

Tsarin tsotsa da zubewa

Shaft na kayan aiki na waje (4) da aka shigar bisa ga ƙarfin kuzari yana motsa zoben gear na ciki (5) zuwa hanyar juyawa da aka nuna. Cika man ta wurin gibin hakori da aka bude a wurin tsotson mai. Ana jigilar mai daga yankin tsotson mai (S) zuwa wurin matsa lamba (P) ta hanyar izinin gefe tsakanin mashin gear waje da zobe na gear. Sakamakon haka, ana fitar da man daga gibin hakori da aka rufe kuma a kai shi tashar mai (P). Wurin tsotsa mai da wurin fitarwa an raba su ta hanyar radial ramuwa kashi (9 zuwa 11) da ragamar gear tsakanin na ciki kayan zobe na ciki da na waje.

Sakamakon axial

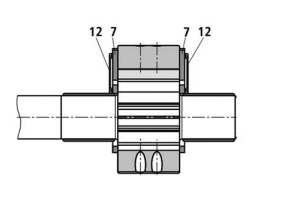

Wurin fitarwa a cikin yankin matsa lamba an rufe shi da farantin rarraba tge iuk (7). Kaskon mai da ke fuskantar nesa da fitarwa, gefe guda ya dawo da matsin lamba (12). Wadannan filayen matsa lamba suna sanya farantin rarraba mai da yanki mai fitarwa ya kai ma'auni, daga madaidaicin tasirin rufewa da aka samu tare da ƙananan asarar inji.

Radiyar Radial

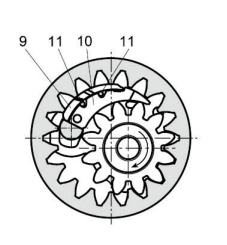

Ƙwararren radial ya haɗa da ƙaramin faranti (9), babban faranti (10) da sandar hatimi (11). Babban farantin jinjirin watan (10) zuwa zagayen farfajiyar tip ɗin bututun shaft ɗin kayan aiki na waje, farantin ƙaramin farantin (9) an haɗe shi da zagaye na ƙarshen haƙorin zoben gear na ciki, da sandar sanyawa. ana amfani da shi don taƙaita motsin farantin jinjirin wata a cikin kewayawa.

Ta wannan hanyar, ana iya raba yankin matsa lamba daga yankin tsotsa ta hanyar daidaitawar sharewa ta atomatik. Wannan buƙatu ne don kiyaye babban ingancin ingancin aiki a koyaushe cikin sa'o'in aiki.

Hakora

A hakori tare da involute flanks siffofi da dogon meshing tsawon ga low kwarara da kuma matsa lamba pulsation sabili da haka yana tabbatar da low amo aiki.

Zayyana Samfura

| VG1 | -63 | R | E | W | -A1 |

| Jerin | Matsala ml/r | Juyawa | Nau'in shaft | Abun rufewa | Zane No. |

| VG0 | 8,10, 13, 16, 20, 25 | Ra'ayoyi daga shaft karshen famfo R= Hannun dama don agogo L=Hannun hagu don karkata agogo baya | E= madaidaicin maɓalli R=Spline shaft | W= NBR V=FKM | A1 |

| VG1 | 25, 32, 40, 50, 63, 50H, 63H | ||||

| VG2 | 80, 100, 125, 145, 160 |

Shafts don famfo

Haɗa famfo

Ra'ayoyin wurin aiki

6S Gudanarwa

Aikace-aikace

Ana iya amfani dashi ko'ina a cikin masana'antu, kamar injin filastik, injin takalma, injin simintin simintin gyare-gyare da injin forklift da sauran masana'antu na tsarin hydraulic, musamman don servo m mitar tuƙi makamashi ceto tsarin.

Abubuwan da ake kulawa don amfani

1. Shigar famfo mai

- Kamar yadda zai yiwu, ana amfani da haɗin kai mai sassauƙa don haɗawa tsakanin famfo famfo da motar motsa jiki don guje wa lokacin lanƙwasa ko bugun axial. Matsakaicin kuskuren coaxial da aka yarda da shi tsakanin famfo shatf da ramin mota shine 0.15mm.

2. Haɗin shigarwa da fitarwa

- Zaɓi diamita na ciki na bututu bisa ga tashar man fetur na famfo mai (mafi kyawun saurin shigarwa shine 0.6-1.2m / s);

- Girman ƙira na layin bututun tsotsa dole ne ya dace da matsi mai aiki mai izini (cikakkiyar ƙimar 0.8bar zuwa 2bar), kuma dole ne a guji lanƙwasa layin bututun tsotsa da haɗuwa da bututun tsotsa da yawa;

- Idan ana amfani da fliter tsotsa mai, ana ba da shawarar cewa za a zaɓi tacewar mai gwargwadon matsakaicin kwararar famfon mai, wanda aka ninka ta hanyar adadin sau 2-3, kuma cikakkiyar daidaiton tacewa shine 50-180um. Dole ne a tabbatar da cewa ko da tace ta gurɓace, ba za ta wuce mafi ƙarancin matsi na aikin shigar da tsarin ba;

- Zurfin nutsarwa na bututun tsotsa da aka zaɓa yakamata ya kasance mai zurfi gwargwadon yiwuwa. Bai kamata a samar da igiyoyin Eddy ba ko da a matsakaicin matsakaicin magudanar ruwa, in ba haka ba zai zama haɗarin tsotsawar iska da saki.

- A cikin ƙirar bututun tsotsa, ba a ba da shawarar shigar da mashin mai a tsaye a ƙasa ba. Idan tankin mai yana ƙarƙashin famfon mai, ya kamata mashigar mai ya kasance sama ko a bangarorin biyu a kwance.

3. Haɗin famfo

- Lokacin haɗa famfo, ya zama dole don tabbatar da cewa kowane mataki ya dace da ranar aiki da aka halatta na nau'ikan famfo masu dacewa;

- Jagoran jujjuyawar duk famfunan da aka haɗa dole ne ya zama iri ɗaya;

- Za a samar da famfo tare da matsakaicin karfin juyi, sauyawar canji ko kayan aiki da aka yi amfani da su azaman matakin farko na famfon da aka haɗa;

- Matsakaicin jujjuyawar tuƙi dole ne mai tsara aikin ya bincika don aikace-aikace iri-iri.

Matsakaicin karfin juzu'i da aka halatta (Nm)

Jimlar karfin jujjuyawar famfon ɗin da aka haɗa ba zai wuce matsakaicin ƙarfin tuƙi ba.

Ba a yarda da haɗakar numfashi ba.

Zane na famfo na baya dole ne ya zama "R" (spline).

4. Aikin farko

- Bincika ko an shigar da tsarin hydraulic daidai kuma an haɗa shi a farkon farawa;

- Kafin aiki, ya kamata ta hanyar tsotsa tubing ko flowline na ciki cike da na'ura mai aiki da karfin ruwa famfo, mai taimako bawul, bude tsarin a karkashin yanayin da wani load aiki Motors, zauna isa lubrication man famfo, da kuma sallama da iska a cikin bututu (mai ne Ba a saita bawul ɗin taimako ba, kamar tsarin zai iya amfani da haɗin gwiwar fitarwa na famfo kaɗan, wasu hanyoyin, don zubar da iskar gas Lokacin da kumfa ba ya bayyana a cikin man da aka ɗora, za a kulle sashin da aka saki daidai da ƙayyadaddun juzu'i : lokacin amfani da wannan hanyar, dole ne a ƙarƙashin yanayin ƙarancin ƙarfi kuma tabbatar da cewa matsin lamba baya tashi.

- Rashin iya fara lodi, in ba haka ba zai haifar da lalacewa na ciki na famfo mai.

- Bayan maimaita aikin digo, sautin tsotsa zai ɓace. Idan sautin haɗewar iska bai ɓace ba bayan maimaita aikin digo na sau da yawa. Ya kamata ya zama cewa akwai zubar da iska a cikin bututun a gefen shiga.

5. Kulawa

- Domin inganta sabis daga cikin famfo mai, da mahaukaci vibration, amo, mai zafin jiki, mai yanayin na'ura mai aiki da karfin ruwa tsarin, ko akwai kumfa a cikin tanki da kuma ko akwai leaks da sauran matsaloli ya kamata a duba akai-akai da kuma kiyaye a cikin. lokaci;

- Dukkan famfunan mai sun ci jarabawar aiki kafin su bar masana'antar. Duk wani kamfani ko mutum ba zai sake hadawa, sake hadawa ko canza fanfunan mai ba tare da izinin kamfani ba. Idan aka harhada, sake hadawa ko canza fanfunan mai ba tare da izinin kamfanin ba, ba ya cikin iyakokin rahoton gyara kamfanin kuma kamfanin ba zai dauki wani nauyi ba.