Factory directly supply Vicks Servo System Export to Romania

Factory directly supply Vicks Servo System Export to Romania Detail:

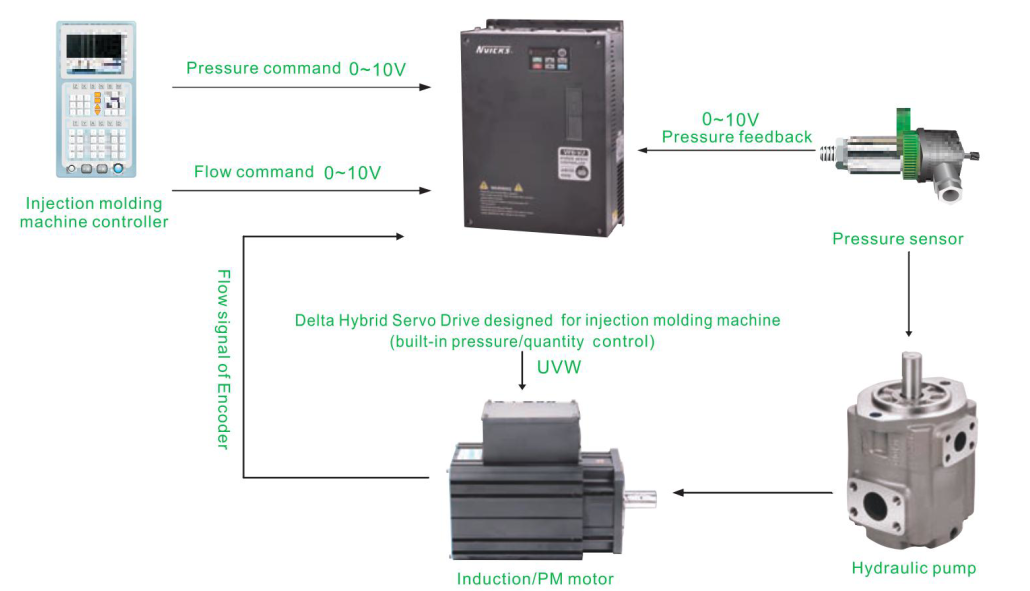

Injection Molding Machine Hydraulic System

Structure of Hydraulic Servo System

After getting the pressure and flow command from the injection molding machine, it performs PID calculation with actual pressure and speed feedback to drive the servo motor and hydraulic pump with a fast response time and high repeat accuracy.

Standard Configuration

Optional Accessories

Features of Hydraulic Energy System ( Five features)

Main power consumption of traditional injection molding machine

When using a hydrualic system, the power consumption is more than 75% of the whole injection system. Different pressures and flows are required during the process, including mold closing, injection, holding pressure and mold openin. When the flow and pressure requirements exceed the settings, the relief or proportional valve will be adjusted, resulting in a 40%-75% higher power consumption.

Top Five Advantages

Usage:

How to select the right Hybrid Energy System

(1) Motor Power Selection

● Required torque (Nm) T= q. ∆ p

2π·ηm

● Output power (kw) P=2π·T·n = T · n = Q·∆ p

60,000 9550 60·πη

q: cc/rev Displacement (cm3) n: Rotation speed ∆ p: Valid pressure difference (Mpa)

Q: Required flow L/min ηm: Pump mechanical efficiency ηt: Pump total efficiency

(2) Solution for Signal Interference

When the drive is installed at the control panel, protection for the signal interference are:

● The wirings of main circuit and control circuit must be separate.

● Proper grounding when necessary

● Use shielding cable for the control circuit

● Use shielding wire for the main circuit wiring

(3) How to Choose a Suitable Hybrid Servo Drive and Motor

In actual applications, the selection of hybrid servo drive and motor wikl be different due to different oil systems.

In the following examples a flow rate of 64L/min and a max. Holding pressure of 17.5 Mpa are used.

● Displacement of Hydraulic Pumps: get the displacement of hydraulic pump (cc/rev) from max. System flow (L/min)

Example: Assume that max. system flow is 64L/min. and max. motor speed is 2000rpm. The displacement of hydraulic pump will be 64/2000*1000=32cc/rev

● Max. motor torque: get the max. torque from max. pressure and the displacement of hydraulic pump

Example: Assume that the max. pressure is 17.5 Mpa and the displacement of hydraulic pump is 32cc/rev. The torque will be 17.5*32*1.3/(2p)=116Nm ( the factor is for 1.3 for compensation of total system losses and it can be changed to 1.2 to 1.3 as required )

● Rated motor torque and rated motor power: The required torque for the holding pressure at the max. pressure should be double of the rated motor torque or less ( use the data provided from the motor plant as the first priority ). Because the motor temperature operated under this situation is easily over temperature. Assume that we choose the double of the rated torque, the motor cab be 9.1kW* with the rated speed 1500rpm when the rated motor torque is 58N-m.

*Motor Power Formula: P(W)=T(N-m)Xw (rpmX2π/ 60)

● Max. Motor Current:

If getting the coefficient kt (Torque/A)=3.31 in the motor specification, max. current is about 115/3.31=35A when the max. Torque is 116N-m.

● Select the Right Drive: Please choose the right drive by the customers’ requirement. Assume that the ability of drive’s overload is 150% for 60 seconds and 200% for 3 seconds. When the holding pressure is at max. pressure 17.5 Mpa with 32cc/rev hydraulic pump, the motor current it requires is 35A.

Note If there is no suitable motor, please use the next higher power motor.

Please contact Delta if you have any questions about hybrid servo drive or integration with your current system.

Product detail pictures:

Related Product Guide:

Why every website owner needs Google Analytics

To fulfill the customers' over-expected fulfillment , we have now our solid staff to deliver our greatest general assistance which includes internet marketing, product sales, creating, manufacturing, excellent controlling, packing, warehousing and logistics for Factory directly supply Vicks Servo System Export to Romania, The product will supply to all over the world, such as: Chicago, Romania, Albania, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.