China Factory for China Promotional Good Quality High Speed Pet Bottle Injection Blow Moulding Automatic Blowing Machine

We’ve lots of great employees associates excellent at promoting, QC, and working with types of troublesome problem from the manufacturing process for China Factory for China Promotional Good Quality High Speed Pet Bottle Injection Blow Moulding Automatic Blowing Machine, We welcome new and aged buyers from all walks of lifetime to make contact with us for potential small business associations and mutual success!

We’ve lots of great employees associates excellent at promoting, QC, and working with types of troublesome problem from the manufacturing process for China Blow Molding Machine, Plastic Bottle Blowing Machine, we’re fully determined to control the whole supply chain so as to offer quality products and solutions at competitive price in a timely manner. We have been keeping up with the advanced techniques, growing through creating more values for our clients and society.

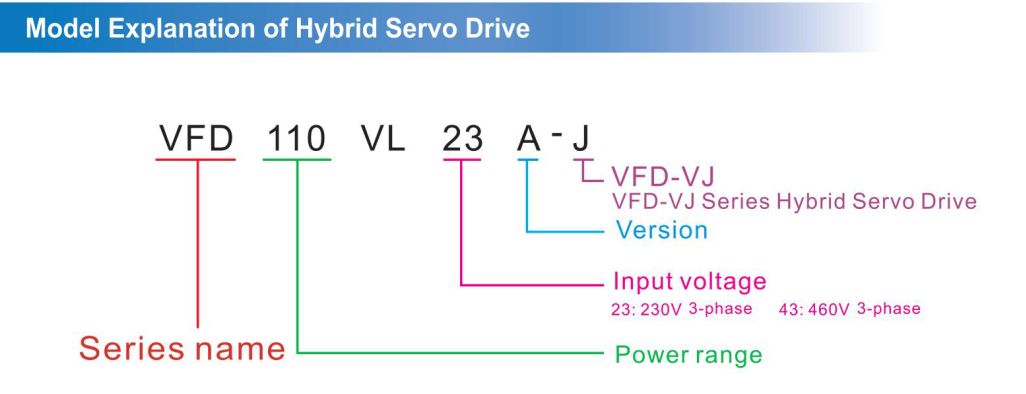

Vicks Servo System Delta Drive

Technical Data

| 460V | Frame | C | D | E0 | E3 | E2 | |||||||||

| Model Number VFD-___VL43_-J | 055A | 075A | 110A | 150B | 185B | 220A | 300B | 370B | 450B | 550A | 750A | ||||

| Power (kW) | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | ||||

| Horsepower (HP) | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 75 | 100 | ||||

| Output | Max. Current (A) (continuous 60 seconds ) | 21 | 27 | 36 | 46 | 58 | 62 | 102 | 124 | 155 | 187 | 255 | |||

| Max. Current (A) (continuous 20 seconds ) | 25 | 32 | 42 | 54 | 68 | 78 | 120 | 146 | 182 | 220 | 300 | ||||

| Input Current (A) | 14 | 18 | 24 | 31 | 39 | 47 | 56 | 67 | 87 | 101 | 122 | ||||

| Power | Input Voltage Tolerance | 3-Phase 380~480V, 50/60 Hz | |||||||||||||

| Mains Voltage Tolerance | ±10% (342-528V) | ||||||||||||||

| Mains Frequency Tolerance | ±5% (47-63Hz) | ||||||||||||||

| Weight (kg) | 8 | 10 | 10 | 10 | 10 | 13 | 13 | 28 | 36 | 50 | 50 | ||||

| General Specifications | Control Method | SVPWM | |||||||||||||

| Speed Detector | Resolver | ||||||||||||||

| Speed Input Command | DC 0~10V, support 3-point adjustment for analog inputs | ||||||||||||||

| Pressure Input Command | DC 0~10V, support 3-point adjustment for analog inputs | ||||||||||||||

| Pressure Feedback Command | DC 0~10V | ||||||||||||||

| General Input Signal | 5 ch DC24V 8mA | ||||||||||||||

| General Output Signal | 2 ch DC24V 50mA, 1 ch Relay output | ||||||||||||||

| Analog Output Voltage | 1 ch dc 0~10V | ||||||||||||||

| Optional Accessories | Speed Feedback PGA Card | Necessary (EMVJ-PG01R) | |||||||||||||

| Brake Resistor | Necessary (refer to appendix A) | ||||||||||||||

| Pressure Sensor | Necessray, only pressure sensors with output signal 0~10V can be used ( max. pressure value can be set by Pr. 00~08) | ||||||||||||||

| EMI Filter | Optional ( refer to Appendix A) | ||||||||||||||

| Protections | Motor Protection | Electronic thremal relay protection | |||||||||||||

| Over-current | 300% of rated current | ||||||||||||||

| Ground leakage current | Higher than 50% rated current | ||||||||||||||

| Voltage Protection | Over-voltage Level: Vdc>400/800V; Low-voltage Level: Vdc<200/400V | ||||||||||||||

| Mains Input Over-Voltage | Varistor (MOV) | ||||||||||||||

| Over-temperature | Built-in Temperature Sensor | ||||||||||||||

| Environment | Protection Level | NEMA 1/IP20 | |||||||||||||

| Operation Temperature | -10℃~45℃ | ||||||||||||||

| Storage Temperature | -20℃~60℃ | ||||||||||||||

| Humidity | 90% RH (non-condensing) | ||||||||||||||

| Vibration | 1.0G 20Hz, 20~60Hz 0.6G <20Hz: 1.0G, 20 to 60 Hz: 0.6G | ||||||||||||||

| Cooling System | (RUN, STOP) Force cooling (RUN, STOP) | ||||||||||||||

| Installation Location | Altitude 1,000m or lower (keep away from corrosive gasses, liquid and dust) | ||||||||||||||

| Certifications | CE | ||||||||||||||

Note: Bulit in brake chopper for models 22kw and below